Tips for Building a Storage Shed

Here are some great tips for building a yard shed that will make it easier to build, a pleasure to look at and a more practical storage or work space.

Here are some excellent tips taken from our pros’ 50 years worth of experience in designing yard sheds. These tips will make your project easier, more economical and help you add practical features that will make your shed even more useful.

By the DIY experts of The Family Handyman Magazine

Fast and lasting roof

Metal roofing makes financial sense

Metal roofing costs about twice as much as asphalt shingles. But on a midsize shed, you’ll only spend an extra $100 to $200. And that’s a bargain when you consider the benefits. A metal roof typically lasts 30 to 50 years and instead of covering the whole roof with plywood, you just nail a few 2×4 “purlins†across the rafters. Screwing the big metal panels to the purlins is much faster than nailing on hundreds of shingles. To find manufacturers, search online for “metal roof.â€

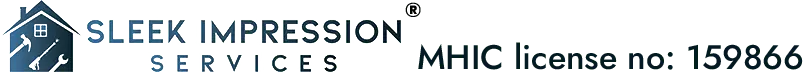

Easy tool access

Build a tool locker for frequently used items

A shallow tool locker on the side or back of a shed offers quick, easy access to lawn and garden gear. To build this tool locker, we constructed an interior wall 12 in. from the back of the shed, covered the studs with pegboard and installed a pair of steel prehung doors ($110 each) inside out so they swing outward. Homemade or sliding doors would work well too.

Simplified floor and foundation

Alternatives to a concrete slab

Pressure-treated lumber laid on a bed of gravel gives you a fast, easy foundation that will last for decades. Or lay joists on the wood foundation and cover them with plywood, just like the floors in most homes are built. For a floor that’s more durable than plywood, fill the wood foundation with gravel and lay cement pavers, just like for a paver patio. A paver floor allows water to drain through, so it’s perfect for a gardening shed and you can rinse the floor clean with a hose.

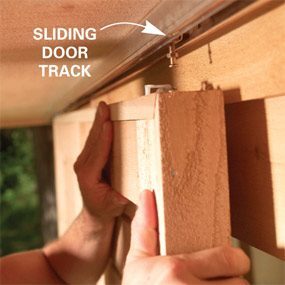

Big doors the easy way

Don’t paint wood

Consider alternatives to wood

If you want your shed to have a rustic, natural look, you can’t beat stained wood. But if you plan to paint your shed, try these long lasting materials:

- Fiber cement usually costs less than wood, holds paint much longer and never rots.

- Composite trim (made from wood fiber and plastic resins) can be cut, nailed or shaped with a router just like wood.

- PVC plastic trim is a more expensive alternative, costing about the same as perfect, knot-free wood. But it will last virtually forever.

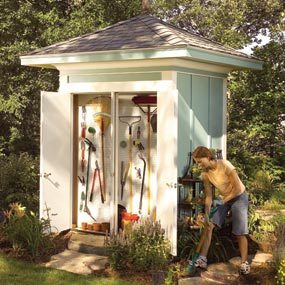

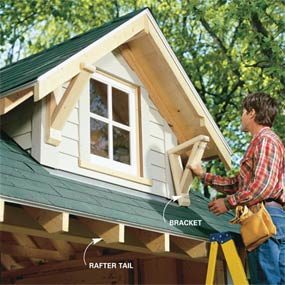

Dress it up with details

Small details can make your shed shine

A few decorative details make all the difference between a show-off shed and a backyard eyesore. A dormer or front porch can dress up a shed, but smaller details can do the trick too. Features like exposed rafter tails, simple decorative brackets, corner boards, a cupola or a gable window are great ways to add charm without adding a lot of work.

Frame the roof flat on the ground

Prebuilt roof trusses save time and work

If you frame your roof the traditional way, one rafter at a time, you’ll spend half the day crawling up and down ladders. With prebuilt roof trusses, you’ll cut out most of the ladder work, saving time and sparing your knees. Manufactured roof trusses in standard sizes are surprisingly cheap—often just a few bucks more than the lumber alone would cost. Contact any home center or lumberyard for prices and options.

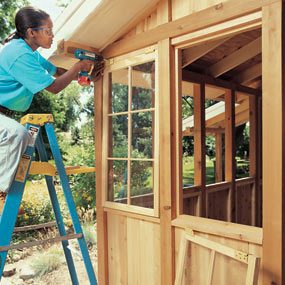

Cheap windows with charm

Barn sash windows add character

“Barn sash†windows are the simplest windows you can get—basic wood frames, single-pane glass and dividers for classic charm. That simplicity makes them inexpensive ($45 for a 22x 42-in. version) and versatile. You can install them upright or sideways, screw them in place permanently, or hinge them on the side or top. Some home centers carry them, but most don’t. Call local lumberyards or ask a manufacturer to recommend a local dealer. To find manufacturers, search online for“ barn sash.â€

Quick, inexpensive skylights

Plastic dome skylights cost less

Skylights let a flood of overhead light into a shed and—unlike windows—leave wall space free for hanging storage and shelving. Skylights made for houses are pricey, but there’s an inexpensive alternative. Plastic dome skylights start at about $45 and are easy to install. Just cut a hole in the roof sheathing, nail the skylight into place and shingle around it. Plastic skylights aren’t exactly attractive, so place them on the side of the roof that’s least visible.

A better way to trim

Use an 18-gauge brad nailer

You don’t need to buy an expensive nailer for exterior trim. An inexpensive little 18-gauge brad nailer can do the job almost as fast. Since those skinny brads don’t have enough holding power to keep large trim in place permanently, you need to first lay on a couple of generous beads of construction adhesive. Then tack the trim into place, using just enough brads to hold it while the adhesive hardens. Unlike thicker nails, brads rarely split the trim and you’ll have only a few tiny holes to fill.